Analyze the factors that affect the bar code level

color

When matching with empty colors and empty faces, the contrast of empty colors must be ensured. The color of the bar can be dark blue, dark green, dark brown or black, and the color of the empty space can be red, orange, yellow or white. Black and white is the best collocation. Gold and silver are not available.

When printing bar code symbols on transparent materials (such as plastic, glass, etc.), do not print only the color of the strip without printing the background color (empty color). Otherwise, the scanner can not collect the empty reflection signal, can not read. Therefore, transparent material printed bar code must first preprint background color.

size

According to the size of the outer package of the commodity and the allowed printing area, select the barcode amplification factor within the range of 0.8-2.00 times of the standard barcode size (standard barcode refers to the barcode with an amplification factor of 1.00, and its size is 37.29*26.26 mm).

Bar height: The height cannot be less than 1/3 of the standard height.

Blank space left and right of bar code: The safe range of bar code, which should have more than 2.5mm blank space away from the edge.

position

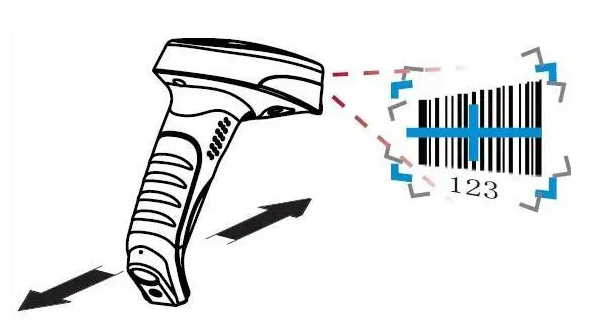

The location of the bar code symbol should be determined in accordance with the principle of no deformation, easy to read.

Bar code surface curvature shall not exceed 30 degrees.

Do not place the bar code in the position with tangents.

The bar code must be at least 5 mm away from the edge, dial, crease or corner of the package.

Bar code grade refers to the quality of the printed or printed bar code.

So the design of qualified bar code mainly depends on the printing or printing effect.

CORELDRAW does not control the bar code level.

Software such as CORELDRAW cannot guarantee that the bar code is scaled correctly. Therefore, the bar code that may cause good printing or printing effect can not be scanned.

There are many possibilities of bar code grade:

1, the use of bar code editing software problems, such as the bar code of the software itself is not standard and other factors, you use what bar code software.

2. Printing method, do you use bar code printer to print, or printing press, if it is the use of label printer, and with the bar code machine with the barcode software, as long as the quality of consumables is not too bad, the printed bar code grade can generally reach C level or above.

3, the layout problem, this is actually a bar code design software problem.

All the production of bar code software can not control the bar code pen level, even professional bar code editing software is not good, if it can be controlled, no one will buy bar code detector to detect whether the bar code level is qualified.